Products Details

| GB | / |

| UNS | C17500 |

| EN | CW104C/CuCo2Be |

| JIS | / |

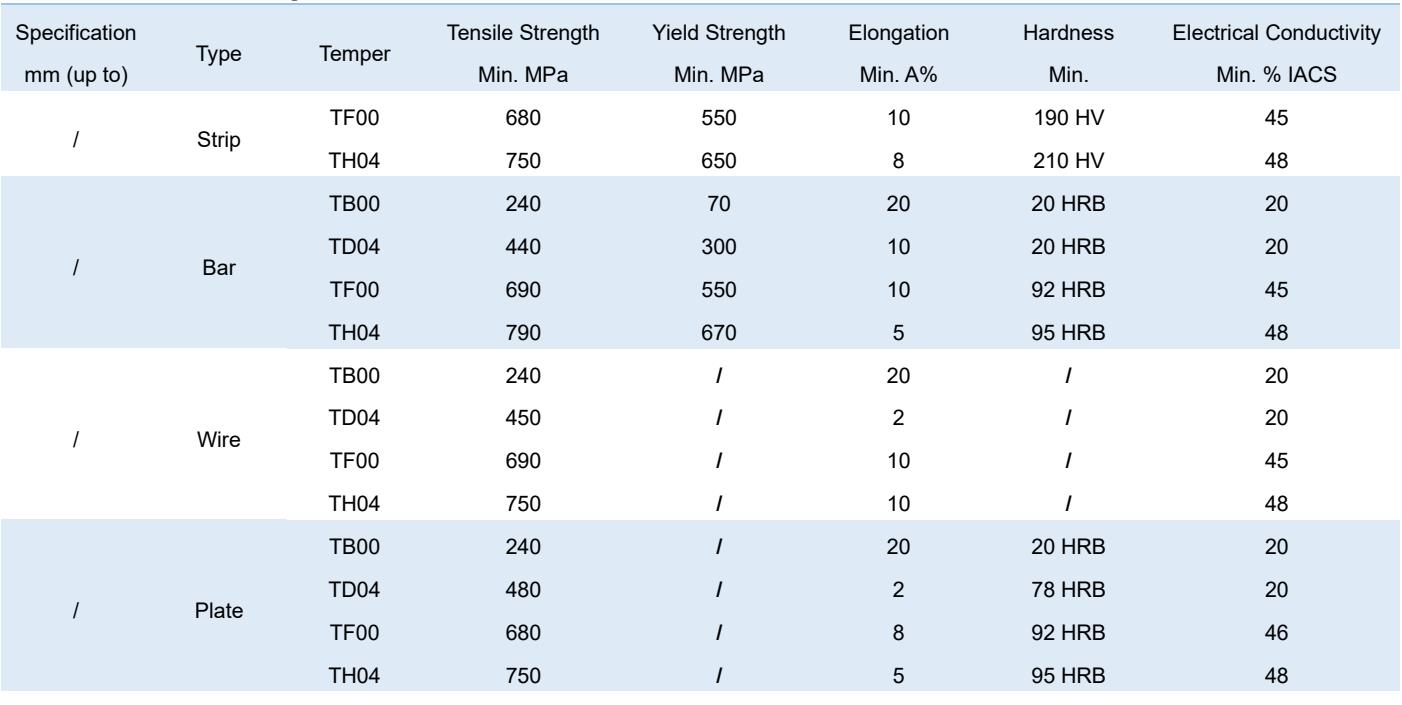

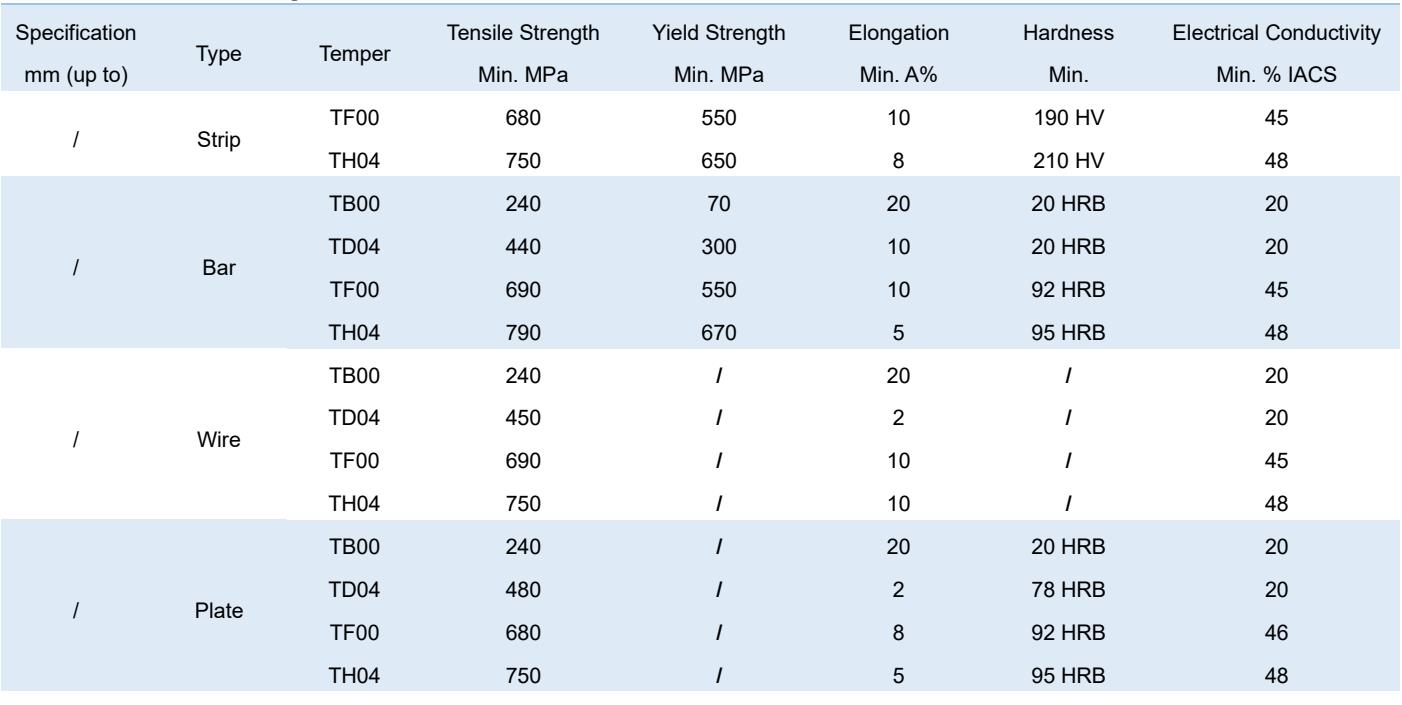

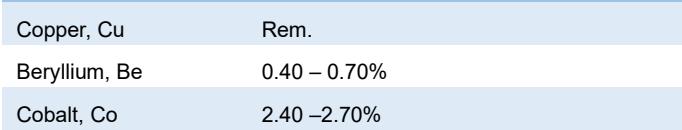

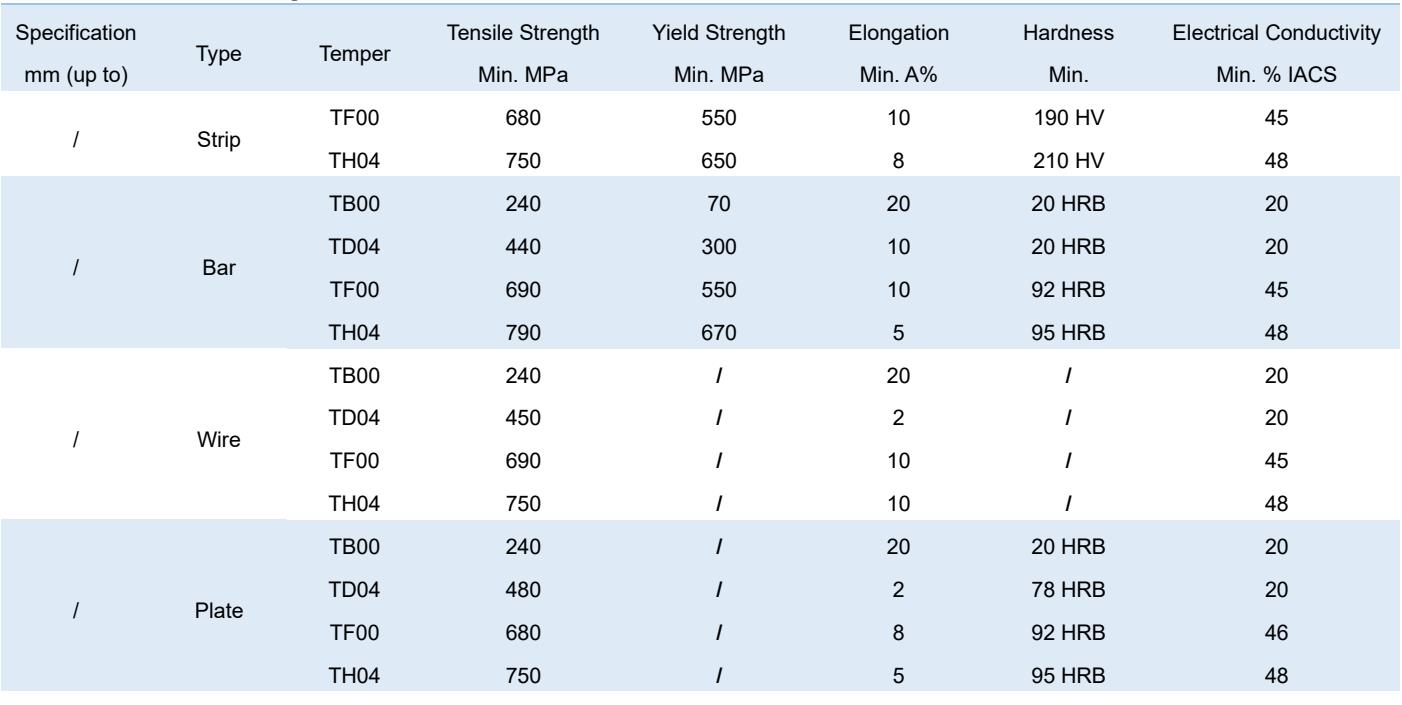

CAMK17500 offers good strength and hardness characteristics coupled with conductivity in the range of 45-60 percent of copper with ultimate tensile and hardness properties approaching 140 ksi and RB 100 respectively. And it has a unique combination of relatively high electrical and thermal conductivity, and also available in wrought product forms,it is a heat treatable copper alloy with a high tensile strength. It can be supplied fully hardened, and have good form. It is utilized when a combination of very good mechanical strength along with moderate electrical and thermal conductivity is required.CAMK17500 is primarily utilized in the industry applications that require most highly thermal or electrical conductivity. 1. Electrical Industry: Fuse Clips, Switch Parts, Relay parts, Connectors, Spring Connectors. 2. Fasteners: Washers, Fasteners. 3. Industrial: Springs, Seam Welding Dies, Resistance Welding Equipment, Resistance and Spot Welding Tips, Tooling for Plastic Moulds, Die–Casting Plunger Tips

K24 Turbo,

Car Wheel Parts,

Bucket Pressure Washer,

Metal Strip,

Advanced Copper Alloys,

Copper Zirconium,

Bronze Stainless Steel,

Copper Germanium Alloy,

Pressure Washing Vinyl Siding,

Power Washing Trailer,